shear stress equation from tensile and compressive tests|how to calculate shear strength : importer When does a state of direct shear exist in a material? Single shear vs. double shear for pinned/bolted connections. Relate shear stress and shear strain. Calculate normal and shear . Resultado da 13 Dec 2022, 14:30. 🔄Renan Franco - OnlyFans (+250 mídias)🔥👇. 🚨 https://encurtandourl.com/u9wEL. channel: t.me/OnlyFlix2. 2.4k 0 19 2 10. OnlyFlix🆕🔥. 13 Dec 2022, 05:59. 🇧🇷 Boa noite, .

{plog:ftitle_list}

web17 de nov. de 2023 · FIRST DEPOSIT BONUS 118%. First Deposit Bonus 118%. Deposit 100 pesos to get a bonus of 118. The maximum bonus is 1088PHP. You can play slot .

If instead of applying a force perpendicular to the surface, we apply parallel but opposite forces on the two surfaces we are applying a shear stress. This is illustrated in the following figure:

sealey ct955 compression tester

The driveshaft, highlighted in the box labeled B, is experiencing torsional .A. force equilibrium. when the bar is stretched, the resulting stress are tensile stress, if the bar is compressed, the stress are compressive stress. the stress. acts in the direction . For compressive strains, if we define \(\delta l=l_{0}-l>0\) then Equation \ref{26.2.3} holds for compressive stresses provided the compressive stress is not too large. For many materials, Young’s Modulus is the same .

When does a state of direct shear exist in a material? Single shear vs. double shear for pinned/bolted connections. Relate shear stress and shear strain. Calculate normal and shear .A direct tensile or compressive stress will cause a direct strain and Direct stress/direct strain = E where E is the modulus of elasticity or Young's modulus. Shear stress will produce a shear .Shear Stress Equations and Applications. General shear stress: The formula to calculate average shear stress is. where τ = the shear stress; F = the force applied; A = the cross .

The shear strain is defined to be the ratio of the horizontal displacement to the height of the block, δ x α = . (26.3.2) h. For many materials, when the shear stress is sufficiently small, experiment .

This physics provides a basic introduction into stress and strain. It covers the differences between tensile stress, compressive stress and shear stress. It provides the equations.

The shear stress is defined to be the ratio of the tangential force to the cross sectional area of the surface upon which it acts, \begin{equation}\sigma_{S}=\frac{F_{\tan .

Tensile stress and strain occur when the forces are stretching an object, causing its elongation, and the length change Δ L Δ L is positive. Compressive stress and strain occur when the forces are contracting an object, causing its shortening, . The image below shows a visual comparison of before and after testing and how tensile stress impacts a material versus how compressive stress affects it. [IMAGE] Comparing These Stress Types. The main .Normal Stresses. A beam subjected to a positive bending moment will tend to develop a concave-upward curvature. Intuitively, this means the material near the top of the beam is placed in compression along the \(x\) direction, with the .

bar is compressed, the stress are compressive stress the stress " acts in the direction perpendicular to the cut surface, it is referred as normal stress, another type of stress is called shear stress sign convention of the normal stresses are : tensile stress as positive and compressive stress as negative Unit of stress :Tensile, Compressive and Shear Tests 3.1 Stress and Strain When a force is applied to a material, a stress will be developed within the . hardening exponent and the true stress-true strain equation is an empirical . 24 TESTING OF MATERIALS expression for work hardening. Instability and necking of a ductile metal

Fig. 1 shows the compression test curve of the powder, which reflects the volume change of the powder bed under the action of normal stress. When the particle size is large, the volume of the bed does not change significantly. When the particle size of powder is smaller, the particle gap shrinks and the bed volume changes greatly under the action of larger normal .Compression or shear strength of a wood beam or truss used extensively for construction can be calculated based on the following equation: Sigma (σ) = P/A, where σ is stress, P is load and A is surface area. The shear stress is defined to be the ratio of the tangential force to the cross sectional area of the surface upon which it acts, \begin{equation}\sigma_{S}=\frac{F_{\tan }}{A}\end{equation} The shear strain is defined to be the ratio of the horizontal displacement to the height of . the tensile force stressing the wire is \begin{equation}F .Shear Stress. Stress parallel to a plane is usually denoted as "shear stress" and can be expressed asτ = F p / A (2). where. τ = shear stress (Pa (N/m 2), psi (lb f /in 2)). F p = shear force in the plane of the area (N, lb f). A = area (m 2, in 2). A shear force lies in the plane of an area and is developed when external loads tend to cause the two segments of a body to slide .

Tensile and Compression Testing. Tensile and Compression testing is the generic name for many types of tests such as pull test, tension test, load resistance test, and many more. This assessment usually occurs during the design verification testing stage so device manufacturers can determine if the design can withstand mechanical forces.

Introduction. The Brazilian Test is a laboratory test conducted in rock mechanics to indirectly determine the tensile strength of rocks. The tensile strength of rock materials is an important parameter in designing a geotechnical project since it is significantly lower than the rocks’ compressive strength.

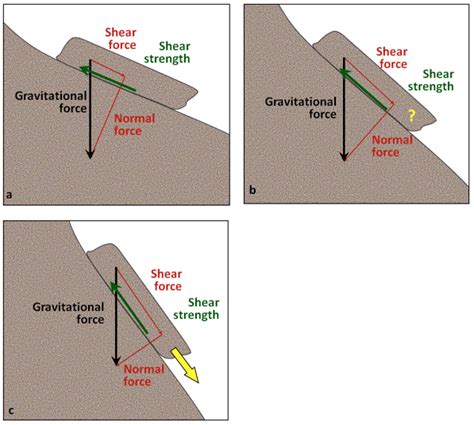

shear stress vs strength

stresses provided the compressive stress is not too large. For many materials, Young’s Modulus is the same when the material is under tension and compression. There are some important exceptions. Concrete and stone can undergo compressive stresses but fail when the same tensile stress is applied. The tensile test is conducted by use of a tensile testing machine or universal testing machine; the latter can be used for both tension and compression tests. In tensile testing, the specimen is firmly held in place by grips of the testing machine (see Fig. 3.4). One end of the specimen is held firm, whilst the other end is pulled by applying a .Tensile stress: Tensile strength: It is defined as force per unit area which is associated with stretching and denoted by σ. It is defined as the amount of tensile stress a material can withstand before breaking and is denoted by s. The formula is: σ = F/A. Where, σ is the tensile stress; F is the force acting; A is the area; The formula is .

In this paper, bending, shear, and compressive tests were conducted respectively on 3-layer CLT panels with a thickness of 105 mm and on 5-layer CLT panels with a thickness of 155 mm, both of which were fabricated with No. 2-grade Canadian black spruce. . Ido et al. analyzed the effects of width and layups on the CLT tensile strength, .Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled . The shear strength properties of rock materials, cohesion and internal friction angle, are determined by carrying out tri-axial strength test on cylindrical core specimens in laboratory. The shear strength of soil formula. The shear strength formula outlines the Mohr–Coulomb envelope, which states that the shear strength is equal to the sum of cohesion (c) and a frictional component (σ’tanφ). The .

It is common during uniaxial (tensile or compressive) testing to equate the stress to the force divided by the original sectional area and the strain to the change in length (along the loading direction) divided by the original length. In fact, these are “engineering” or “nominal” values.

Note that in general, the tensile strength measured using the indirect methods is less than that measured used a direct tension apparatus. 2.5 Shear Tests Direct simple, double or punch shear tests can be conducted on rock. The tests allow a direct measurement of the intact rock shear strength. However, they are difficult to perform.A positive state of shear stress, then, has arrows meeting at the upper right and lower left of the stress square. Conversely, arrows in a negative state of shear meet at the lower right and upper left. Figure 5: Shear strain. The strain accompanying the shear stress \(\tau_{xy}\) is a shear strain denoted \(\gamma_{xy}\).

Forces parallel to the area resisting the force cause shearing stress. It differs to tensile and compressive stresses, which are caused by forces perpendicular to the area on which they act. Shearing stress is also known as tangential stress. $\tau = \dfrac{V}{A}$ where V is the resultant shearing force which passes through the centroid of the area A being sheared.• Ductile materials have a shear strength about one-half of tensile strength. • Brittle materials have a shear strength which can be greater than their tensile strength. Failure line Uniaxial tensile test Uniaxial compression test Torsion test s t In the compression region, the material’s resistance to shear increases 19.5 Coulomb-Mohr .

These tests are denoted as 0T1 to 0T4. The measured load vs displacement (stroke) for each test is shown in Fig. 1.The nominal stress vs. nominal strain plot (the latter calculated as the ratio of the stroke and initial length) is shown in Fig. 2.All specimens exhibit a nearly linear initial region followed by a well-defined peak followed by a sudden or nearly . Compression tests of a polymer structural foam material is covered by ASTM D1621 which specifies the type of compression plates and deflectometer used. The test sample is placed between compression test platens until the cellular structure fails or ruptures. A universal test machine can perform either or both tension and compression tests.

SYNOPSIS. Uniaxial compressive strength (UCS) and shear strength parameters (cohesion and angle of internal friction, C and ϕ) of rocks are important parameters needed for various engineering projects such as tunnelling and slope stability.However, direct determination of these parameters is difficult and requires high-quality core samples for tests. Assuming a pure shear stress state in the center of the wall in diagonal compression tests, the shear and tensile strength of adobe masonry are within the range 0.15–0.2 MPa. The paper shows that results from splitting tests are consistent with those from diagonal compression tests in which the mortar used for the masonry is similar to the .Thus as per this theory, the material of this object undergoes failure when the maximum shear stress developed in an object (`\tau_{max}`) exceeds or becomes equal to the yield shear stress value in a uniaxial tensile test (`\tau_{\text{y. uniaxial}}`). Thus to prevent failure, there should be, Maximum shear stress ≤ yield shear stress (uniaxial)

shear stress equation fluid mechanics

11 de dez. de 2023 · Colaboração para o UOL, em São Paulo. 11/12/2023 20h22 Atualizada em 11/12/2023 21h16. Quatro apostas acertaram as 15 dezenas sorteadas hoje no .

shear stress equation from tensile and compressive tests|how to calculate shear strength